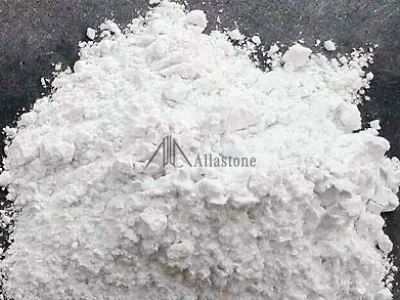

Marble Chips

One of the stone products with a variety of uses is marble chips.

Marble chips are created by stone crushers from the remnants of mines or stone-cutting industries, then marble chips are sorted into various sizes using various procedures. Iran has a large number of natural stone mines, allowing it to produce a wide variety of marble Chips with unique properties and hues. Marble chips come in a variety of sizes, ranging from around 10 cm to stone powder. One of the most well-known marble chips on the market is white marble; calcium carbonate and lime are what give it its white hue.

Because each Marble Chip has unique properties according on its mine and structure, it is used in several work industries.

Marble chips and stone powder have numerous applications outside of construction, including resin and metal manufacture, agriculture, food, and the refining and smelting of metals.

Specifications of Marble Chips

Marble is a stone transformed from limestone, whose general chemical formula is CaCO3, and the molecular shape of calcium carbonate is linear, and the melting temperature of calcium carbonate is 825 degrees Celsius. Calcite, a kind of calcium carbonate that gives stone its strength and hardness, is where marble chips first appeared. It is better to know that this chemical component, which makes up 4% of the earth’s crust and may also be found in animal membranes and eggshells, including those of crabs and snails, is safe.

Marble is resistant to frost, high temperatures, and atmospheric phenomena due to its high density, making marble chips indestructible.

That is why marble chips, particularly white chips, are used on the building’s exterior of the Buildings, concrete production, etc.

In addition to the natural beauty, marble chips for the exterior of the building can significantly reduce your costs. Marble chips are now widely used in landscaping, so you can use a variety of marble chips throughout your property.

In the summer, white or black Marble chips, or even coloured Marble chips, can be used on the soil to prevent moisture evaporation. Furthermore, the use of marble chips in concrete strengthens the concrete.

Various types of Stone chips

Stone Chips have different materials, colors and sizes, each of which has its own characteristics.

The most significant varieties of stone chips and powder are made of limestone powder and limestone chips, dolomite powder and dolomite chips, marble powder and marble chips, calcium carbonate powder and calcium carbonate chips, granite powder and granite chips, and quartz powder and quartz. stone chips are made from a variety of sedimentary, metamorphic, and igneous minerals, just as stone powder and stone chips.

A fascinating issue is the variety of colours found in stone chips, which are also known as black marble chips, white marble chips, orange stone chips, red stone chips, brown stone chips, yellow stone chips, green stone chips, and cream stone chips.

Stone chips are produced in a variety of sizes, including 10 cm and lower sizes, sand sizes below 1 cm, and powder with varied meshes.

Limestone chips and limestone powder

One of the calcium carbonate compounds is limestone, which can be found as stone chips or powder with the chemical formula CaCO3.

Limestone powder is the most popular stone powder in the world because of its various benefits. Construction, road building, agriculture, the chemical industry, steel manufacture, glass production, the production of livestock and poultry, cosmetics and hygiene, food, glazing, and other industries that depend on stone powder all use limestone powder in some form.

It’s a lime Stone powder is used in concrete and construction to strengthen the concrete’s compressive strength and make it impermeable.

Granite chips and granite powder

For some varieties of metamorphic rocks, the terms “granite chips” and “granite powder” are used.

The class of stones known as granite stones includes peridotite, basalt, rhyolite, and diorite.

Compared to other stone chips, the production of granite chips and granite powder is more expensive, but the finished products are more durable than other stone chips.

Dolomite chips or Dolomite stone powder

Dolomite is a type of limestone with the chemical composition calcium magnesium carbonate. It is also known as dolomite chips or dolomite stone powder.

Dolomite stone powder has a higher hardness than limestone stone powder but is not as widely used.

These two types of stone powder are used for comparable things and share many characteristics with limestone chips and powder.

Marble chips and Marble powder

The most well-known and frequently used stone chips on the market are marble chips and marble powder because of the large range of hues and specifications available.

Chips made of marble and limestone resemble one another quite a bit.

Since white stone powder is made from marble chips, the marble chips’ white colour is extremely ideal for the creation of stone powder.

The production of filters, fillers, and additives for the human and animal food sectors, as well as for bleaching and cosmetics manufacturing, are just a few uses for marble stone powder.

Crystal stone chips or quartz chips

One of the most prevalent and hardest natural minerals is quartz, often known as crystal stone, and while it is tough to crush with a stone crusher, stone powder is typically created naturally.

Sand and quartz are exceptionally durable materials.

Sand-like quartz stone is similar to sand, yet it has undergone metamorphosis.

Production of marble chips (stone chips)

There are artificial natural way for producing marble chips, and the artificial method is important to us. The production of stone chips requires a large area (about 7 thousand meters), of course, most of this area is for storing stone chips depots.

Small clods and carcasses from different stone mines, as well as waste and leftover clods from stone-cutting facilities, are the raw materials used to make stone chips. These pieces of stone are loaded and transferred to the stone chips production environment for production, which you can watch the related videos for a better understanding.

The process of producing stone chips is called stone crushing, which has stone crushers, sieves, rails with different technical specifications.

stone chips factories are often next to stone mines or stone production industrial zone. Different stones are put into a chamber that acts as a stone crusher and begin to be crushed; after this, they are moved to another portion by rails and conveyors for crushing with smaller dimensions; finally, they are set up on various sieves to separate different dimensions. which, depending on the size of the sieve, turns the stones over and separates them through a great deal of vibration.

The manufacture of marble chips involves unique processes that vary depending on the desired production equipment and the requirements of the finished product. The machine loads the finished product of various stone chips, which are then moved to their respective sections in the stone chips warehouse based on the colour, material, and size of the stone chips.

Application of marble chips

The application of marble chips has a wide range, so that many explanations can be given for each one, and this is due to the variety of production and the different characteristics of marble chips and stone powder.

Stone chips are always useful to us because they are used in all spaces, including the interior of the building, the exterior and facade of the building, landscaping, decorations, etc., and with a low cost, it can add a lot of natural beauty to the environment.

Marble chips and marble powder are used in industries and productions, including food, pharmaceutical, health, agriculture, petrochemical and many other industries, which shows the high importance of marble chips and stone powder.

Marble chips or stone powder refers to special sizes that are created by crushing marble stone.

White stone powder, one of the varieties of which is calcium carbonate powder, is one of the most popular stone powders on the market.

One of the most significant applications for white marble stone powder is the creation of paper and sanitary cardboard, which is frequently used to make candy boxes, medication boxes, and sanitary products. This process boosts the quality and resilience of paper while lowering its cost.

There are several applications for calcium carbonate and white marble powder, including those in the paper, plastic, paint, adhesive, pharmaceutical, food, agricultural, and building materials sectors.

When making calcium carbide, iron and steel smelters use stone powder as a smelting aid.

In order to manage and enhance the soil, stone powder is employed in agriculture.

Weeds and fungus moulds cannot grow where stone powder has been applied to the ground.

Asphalt, cement, and other building materials are made with the help of stone powder in the construction of roads.

For purposes such as sewage drainage, roadside stabilisation, disinfection, and more, stone powder is used in the construction of roads, railway lines, and shafts.

Additionally, the usage of stone powder in the manufacture of cement lowers environmental contamination and lessens cement permeability.

Due to its quick spread, good gloss, low hardness, and low oil absorption, calcium carbonate powder is employed in the rubber and plastic industries.

For sculpture, marble powder is employed.

Some cosmetics are made using calcium carbonate stone powder.

In order to connect stone and ceramic tiles, stone powder is required.

After the asphalt process, stone powder is used to improve the adherence of asphalt and bitumen.

Because of its antibacterial qualities, stone powder is used in livestock and poultry breeding facilities as well as chicken farms.

There are many colours available in stone powder, and some of these hues work well in projects using natural and durable building colours like white cement.

construction mortar are made from stone powder.

Some sealants and various polymers are made using stone powder.

Some soil minerals are provided for agriculture using stone powder.

Sandblasting involves the use of stone powder.

Water and wastewater treatment, disinfection, and pH correction all require marble powder.

Stone powder in concrete

Stone powder is crucial and utilised in the production of concrete.

Today, stone powder is used in replacement of sand in the production of concrete, and some benefits of doing so include:

The final quality of concrete is improved by using stone powder during production.

Concrete production costs are decreased by using marble powder.

Concrete manufacture with marble stone powder reduces post-curing fractures in the concrete.

When used in the manufacturing of concrete, marble powder boosts the material’s resistance to water and moisture as well as its compressive strength.